Our service is fully comprehensive, and offers great value for money. Our client centric approach takes into all unique requirements into consideration, while providing the most optimised solution in terms of work flows, efficiencies, and compliances. Our process design extends from the animal entering the facility, right until the product is dispatched for retail.

- Single or combined lines for all types of livestock.

- Highly effective cutting systems.

- Optimal exploitation of by-products.

- Tubular track technology for optimised meat transportation.

- Custom-made systems that meet regulation standards.

Process Design

Custom design and formulation of optimal operational processes and production lines.

Architectural

We provide Architectural Design and manage the municipal plans submission procedure.

Engineering

Professional engineering services, including Civil, Structural, Electrical and Mechanical.

HVAC Systems

Design and installation for all Refrigeration and Mechanical Ventilation systems.

Compliance

Provision of Environmental Impact Assessments, and Water Use Licensing.

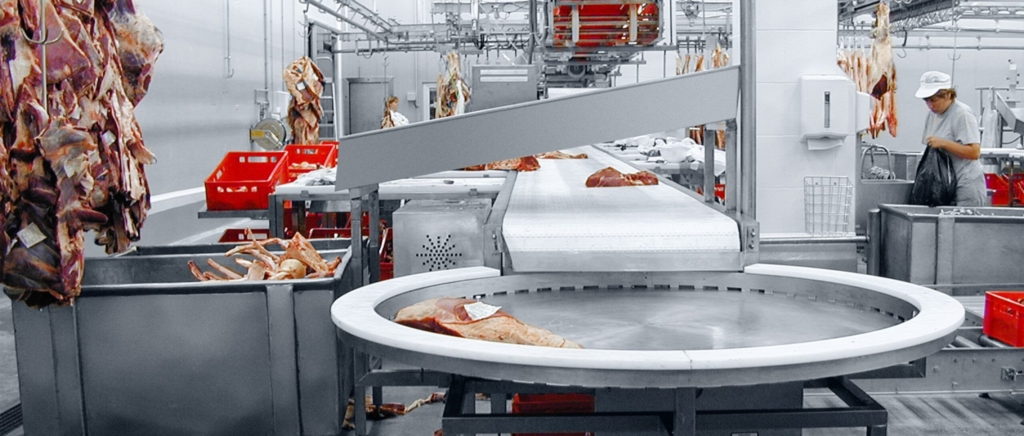

Especially in an abattoir, safety, ergonomics, efficiency and of course hygiene all play a decisive role. Innovative and proven technology from Abattoir Supply Co ensures all of the working procedures in every slaughter-line and significantly improves efficiency. All of our abattoir solutions are precisely adapted to meet our customer needs and the requirements of the respective market.

We offer our customers complete lines which allow for precise, technically correct and hygienic cutting systems of the carcass in suitable portions for consumers and in primal cuts. The customers themselves determine the degree of automation in each case. Our specialists ensure smooth operation of all steps in the process, including a well considered hygiene and logistics concept, to produce products which are always fresh and have maximum storage life.

- Rotary blade saws, bandsaws, breaking saws.

- De-rinding and de-hiding machines.

- Manual or fully automatic conveyor systems.

- Hand knives and various tools.

When slaughtering animals, there are valuable by-products which can make a significant contribution to the value created in the operation. The more precise and hygienic, the more effective the result. So that this result can flow into the overall profitability calculations, all of the processing lines for the by-products – such as blood mixers, blood tanks and intestine cleaning lines, as well as environmentally neutral disposal systems for slaughter waste products are taken into account during planning.

Carcasses can be transported without delay and with minimum effort into the refrigerated rooms, a carefully conceived tubular track concept is required. For this, we plan and build track systems to your requirements to transport cut-up carcasses manually, semi-automatically or fully automatically to and from refrigerated storage rooms, which feature state-of-the-art technology.

- Solid construction using hot-dipped galvanised steel.

- Enhances cost-effective use of the refrigerated areas.

- Manual or fully automatic conveyor systems.

- Hook return systems.